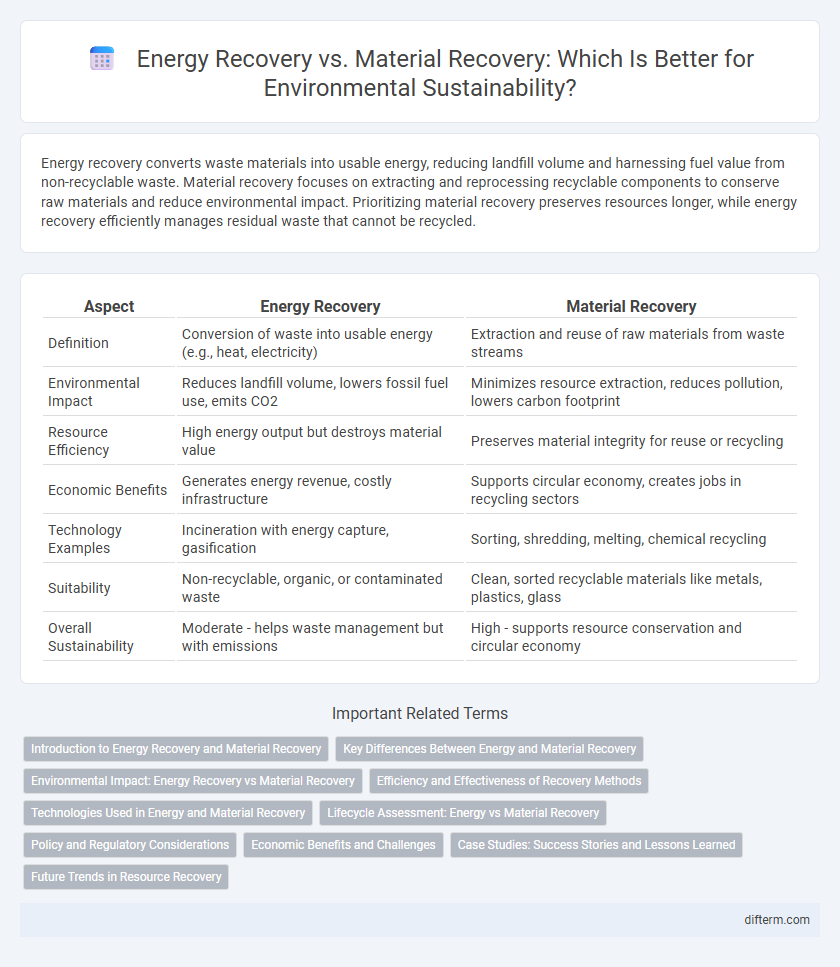

Energy recovery converts waste materials into usable energy, reducing landfill volume and harnessing fuel value from non-recyclable waste. Material recovery focuses on extracting and reprocessing recyclable components to conserve raw materials and reduce environmental impact. Prioritizing material recovery preserves resources longer, while energy recovery efficiently manages residual waste that cannot be recycled.

Table of Comparison

| Aspect | Energy Recovery | Material Recovery |

|---|---|---|

| Definition | Conversion of waste into usable energy (e.g., heat, electricity) | Extraction and reuse of raw materials from waste streams |

| Environmental Impact | Reduces landfill volume, lowers fossil fuel use, emits CO2 | Minimizes resource extraction, reduces pollution, lowers carbon footprint |

| Resource Efficiency | High energy output but destroys material value | Preserves material integrity for reuse or recycling |

| Economic Benefits | Generates energy revenue, costly infrastructure | Supports circular economy, creates jobs in recycling sectors |

| Technology Examples | Incineration with energy capture, gasification | Sorting, shredding, melting, chemical recycling |

| Suitability | Non-recyclable, organic, or contaminated waste | Clean, sorted recyclable materials like metals, plastics, glass |

| Overall Sustainability | Moderate - helps waste management but with emissions | High - supports resource conservation and circular economy |

Introduction to Energy Recovery and Material Recovery

Energy recovery converts waste materials into usable energy through processes like combustion, gasification, or anaerobic digestion, reducing landfill use and generating electricity or heat. Material recovery involves extracting and recycling valuable materials such as metals, plastics, and paper from waste streams, promoting resource conservation and reducing environmental impact. Both methods play crucial roles in sustainable waste management by enhancing resource efficiency and minimizing pollution.

Key Differences Between Energy and Material Recovery

Energy recovery converts waste into usable energy through processes like combustion or anaerobic digestion, prioritizing waste-to-energy efficiency over material preservation. Material recovery emphasizes extracting and recycling raw materials to reduce resource depletion and landfill use, maintaining the integrity of recyclables such as metals, plastics, and paper. Energy recovery is ideal for non-recyclable waste with high calorific value, while material recovery targets waste streams rich in recoverable resources to support circular economy goals.

Environmental Impact: Energy Recovery vs Material Recovery

Energy recovery from waste converts organic materials into usable energy, reducing landfill methane emissions but often releases greenhouse gases and pollutants. Material recovery recycles waste into raw materials, conserving natural resources and minimizing energy consumption compared to producing new materials, leading to a lower overall carbon footprint. Prioritizing material recovery enhances sustainability by reducing environmental impact through resource conservation and pollution reduction.

Efficiency and Effectiveness of Recovery Methods

Energy recovery captures the energy content of waste through processes like incineration, converting waste to usable heat or electricity with high efficiency but often lower overall material preservation. Material recovery emphasizes recycling and reclaiming valuable materials, maximizing resource conservation and reducing environmental impact but typically requiring more complex sorting and processing. Balancing energy recovery's rapid waste volume reduction with material recovery's resource retention optimizes overall environmental sustainability and resource efficiency.

Technologies Used in Energy and Material Recovery

Advanced energy recovery technologies such as anaerobic digestion, gasification, and pyrolysis efficiently convert organic waste into biogas, syngas, or biochar, maximizing energy output from refuse. Material recovery utilizes sophisticated sorting systems including optical sorters, magnetic separators, and eddy current separators to isolate metals, plastics, and paper for recycling, reducing landfill reliance. Innovations in sensor-based automation and machine learning further enhance the precision and efficiency of both energy and material recovery processes in waste management systems.

Lifecycle Assessment: Energy vs Material Recovery

Lifecycle Assessment (LCA) of energy recovery highlights significant reductions in greenhouse gas emissions by converting waste into usable energy, offsetting fossil fuel consumption. Material recovery systems excel in preserving natural resources by recycling materials, reducing the need for virgin material extraction and minimizing environmental degradation. Comparative LCA studies demonstrate material recovery generally yields higher overall environmental benefits due to extended material lifecycles, despite energy recovery's advantages in energy displacement.

Policy and Regulatory Considerations

Energy recovery policies often emphasize reducing landfill use and promoting renewable energy sources, aligning with waste-to-energy (WtE) regulatory frameworks that incentivize combustion technologies. Material recovery regulations prioritize circular economy goals by enforcing stricter recycling mandates, extended producer responsibility (EPR), and landfill diversion targets to maximize resource efficiency. Policymakers balance emissions standards and economic incentives to optimize the environmental benefits of energy recovery while ensuring materials are diverted for reuse and recycling whenever possible.

Economic Benefits and Challenges

Energy recovery from waste offers economic benefits by generating electricity and reducing landfill costs, yet it faces challenges such as high operational expenses and fluctuating energy market prices. Material recovery promotes economic advantages through resource conservation and the creation of secondary raw materials, but it struggles with contamination issues and the need for advanced sorting technologies. Balancing these methods requires assessing local market demand, infrastructure investment, and regulatory incentives to optimize cost-effectiveness and sustainability.

Case Studies: Success Stories and Lessons Learned

Case studies on energy recovery and material recovery highlight significant environmental benefits, including reduced landfill use and lower greenhouse gas emissions. Successful projects such as the Amsterdam Waste-to-Energy plant demonstrate how energy recovery can supplement power grids while advanced material recovery facilities in Sweden achieve high recycling rates exceeding 90%. Lessons learned emphasize the importance of combining efficient sorting technologies with public engagement to maximize resource recovery and minimize ecological impact.

Future Trends in Resource Recovery

Energy recovery techniques, such as advanced thermal conversion technologies, are gaining traction for their ability to efficiently convert waste into usable energy while reducing landfill volumes. Material recovery is evolving through enhanced sorting technologies and AI-driven recycling systems, enabling higher purity of reclaimed materials and expanded circular economy applications. Future trends indicate integrated recovery models combining both energy and materials to maximize resource efficiency and minimize environmental impact.

energy recovery vs material recovery Infographic

difterm.com

difterm.com