SKU (Stock Keeping Unit) is a unique identifier created by a business to track inventory internally, while UPC (Universal Product Code) is a standardized barcode used globally for product identification and sales scanning. SKUs allow companies to categorize products with specific attributes tailored to their inventory systems, whereas UPCs ensure products are universally recognizable across retailers and supply chains. Understanding the distinction between SKU and UPC is crucial for efficient inventory management and seamless product distribution.

Table of Comparison

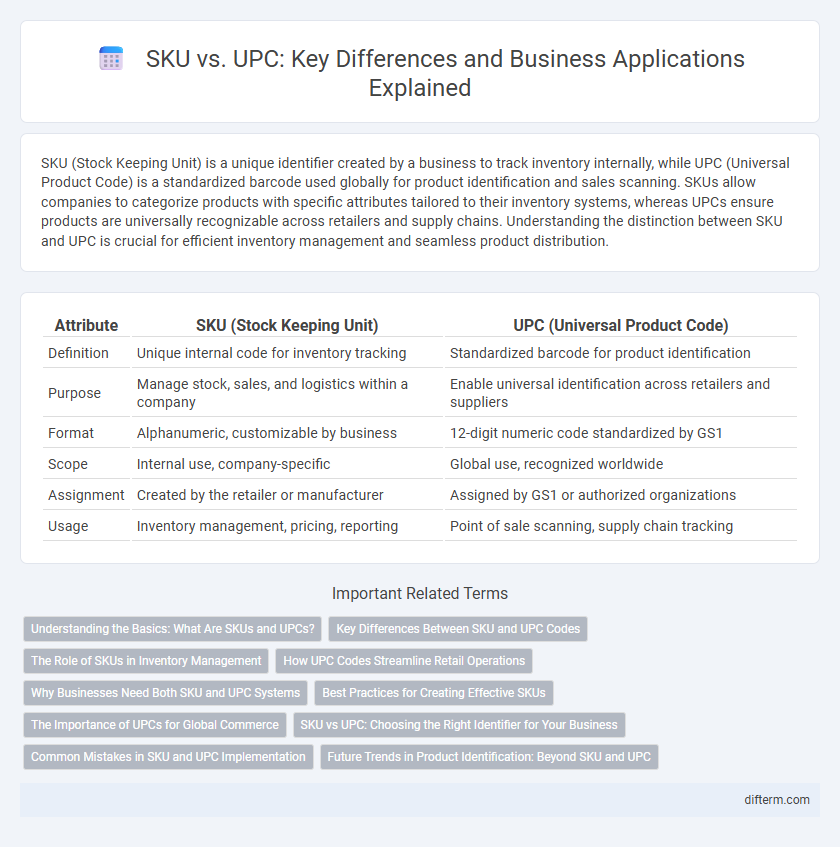

| Attribute | SKU (Stock Keeping Unit) | UPC (Universal Product Code) |

|---|---|---|

| Definition | Unique internal code for inventory tracking | Standardized barcode for product identification |

| Purpose | Manage stock, sales, and logistics within a company | Enable universal identification across retailers and suppliers |

| Format | Alphanumeric, customizable by business | 12-digit numeric code standardized by GS1 |

| Scope | Internal use, company-specific | Global use, recognized worldwide |

| Assignment | Created by the retailer or manufacturer | Assigned by GS1 or authorized organizations |

| Usage | Inventory management, pricing, reporting | Point of sale scanning, supply chain tracking |

Understanding the Basics: What Are SKUs and UPCs?

SKUs (Stock Keeping Units) are unique codes created by retailers to track inventory and manage stock across different locations, often including product attributes like size and color. UPCs (Universal Product Codes) are standardized barcodes assigned by manufacturers to identify products globally, enabling efficient scanning at points of sale. Understanding the distinction between SKUs and UPCs is essential for optimizing inventory management and streamlining supply chain operations.

Key Differences Between SKU and UPC Codes

SKU (Stock Keeping Unit) codes are unique alphanumeric identifiers created by businesses to track inventory internally, enabling precise stock management and sales analysis. UPC (Universal Product Code) codes are standardized 12-digit barcodes assigned by GS1, used globally for product identification and facilitating retail scanning and point-of-sale transactions. The primary difference lies in SKU's custom, internal use versus UPC's universal external application for product identification across retailers and supply chains.

The Role of SKUs in Inventory Management

SKUs (Stock Keeping Units) play a crucial role in inventory management by providing a unique identifier for each product variant, enabling precise tracking of stock levels and sales performance. Unlike UPCs (Universal Product Codes), which are standardized for universal identification, SKUs are tailored by businesses to reflect attributes such as size, color, and model, facilitating efficient categorization and replenishment decisions. Effective use of SKUs enhances inventory accuracy, reduces stockouts, and optimizes supply chain operations.

How UPC Codes Streamline Retail Operations

UPC codes enhance retail operations by providing a standardized method for tracking products, reducing errors in inventory management, and speeding up checkout processes. Unlike SKUs, which are unique to each retailer and vary in format, UPCs offer a universal identification system that facilitates seamless product scanning and data sharing across supply chains. This efficiency leads to improved stock accuracy, faster restocking, and better sales analytics in retail environments.

Why Businesses Need Both SKU and UPC Systems

Businesses need both SKU and UPC systems to enhance inventory management and streamline sales processes. SKU codes offer unique internal tracking tailored to specific product attributes, while UPCs provide universal identification recognized across retail channels. Integrating both systems improves accuracy in stock control, pricing, and supply chain efficiency.

Best Practices for Creating Effective SKUs

Effective SKU creation emphasizes unique, concise identifiers that reflect product attributes such as category, size, color, and style for streamlined inventory management. Unlike UPCs, which are standardized and used globally for scanning at retail points, SKUs are internally tailored to enhance searchability and organization within a specific business system. Incorporating alphanumeric codes and maintaining consistent formatting across all SKUs improves accuracy in tracking sales trends and replenishment cycles.

The Importance of UPCs for Global Commerce

Universal Product Codes (UPCs) are crucial for global commerce as they enable standardized product identification across international supply chains, facilitating efficient inventory management and sales tracking. Unlike SKUs, which are company-specific and primarily used for internal tracking, UPCs provide a universal language recognized by retailers, distributors, and logistics providers worldwide. This common identifier reduces errors, accelerates checkout processes, and supports seamless integration of products into global markets.

SKU vs UPC: Choosing the Right Identifier for Your Business

SKU (Stock Keeping Unit) and UPC (Universal Product Code) serve distinct purposes in inventory management, with SKUs offering customizable identifiers tailored to a retailer's specific product attributes, while UPCs provide standardized barcodes crucial for global product tracking and point-of-sale scanning. Businesses prioritizing internal organization and detailed inventory analysis benefit from implementing SKUs, whereas companies focusing on widespread distribution and universal recognition rely on UPCs to streamline supply chain operations. Selecting the right identifier depends on the business model, product complexity, and market reach, ensuring efficient stock control and seamless customer transactions.

Common Mistakes in SKU and UPC Implementation

Common mistakes in SKU and UPC implementation include confusing the purpose of SKUs and UPCs, leading to inconsistent product identification and inventory errors. Companies often generate SKUs without a standardized format, causing difficulties in tracking and managing products across sales channels. Failing to assign unique UPCs to each product variant results in scanning errors and hampers accurate sales and inventory reporting.

Future Trends in Product Identification: Beyond SKU and UPC

Emerging technologies in product identification are poised to surpass traditional SKU and UPC systems by integrating AI-driven analytics and blockchain for enhanced traceability and authenticity verification. Smart labels embedded with RFID and IoT sensors enable real-time inventory management and customer engagement, transforming supply chain efficiency. Future trends emphasize interoperability and seamless data exchange across platforms to meet the demands of omnichannel retail ecosystems.

SKU vs UPC Infographic

difterm.com

difterm.com