Just-in-time (JIT) inventory management minimizes stock levels by receiving goods only as they are needed in the production process, reducing holding costs and waste. In contrast, just-in-case (JIC) inventory involves maintaining extra stock to mitigate risks of supply chain disruptions, ensuring business continuity during unexpected demand spikes or delays. Balancing JIT's efficiency with JIC's risk management is critical for optimizing operational resilience and cost-effectiveness in varying market conditions.

Table of Comparison

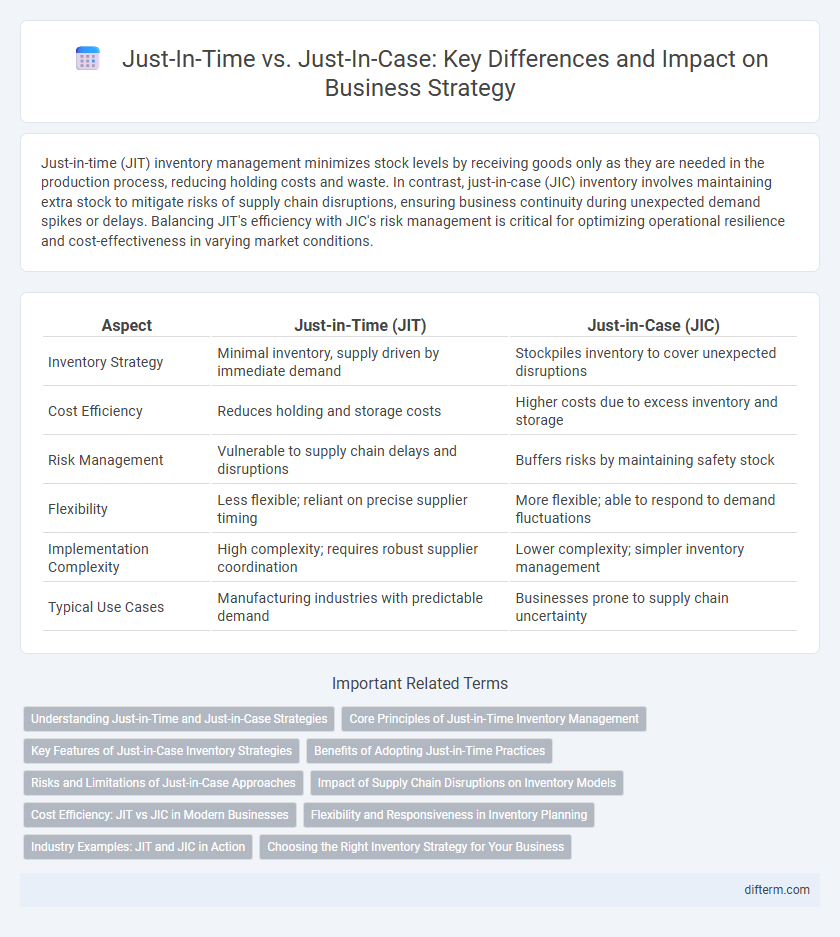

| Aspect | Just-in-Time (JIT) | Just-in-Case (JIC) |

|---|---|---|

| Inventory Strategy | Minimal inventory, supply driven by immediate demand | Stockpiles inventory to cover unexpected disruptions |

| Cost Efficiency | Reduces holding and storage costs | Higher costs due to excess inventory and storage |

| Risk Management | Vulnerable to supply chain delays and disruptions | Buffers risks by maintaining safety stock |

| Flexibility | Less flexible; reliant on precise supplier timing | More flexible; able to respond to demand fluctuations |

| Implementation Complexity | High complexity; requires robust supplier coordination | Lower complexity; simpler inventory management |

| Typical Use Cases | Manufacturing industries with predictable demand | Businesses prone to supply chain uncertainty |

Understanding Just-in-Time and Just-in-Case Strategies

Just-in-Time (JIT) strategy minimizes inventory by synchronizing production schedules closely with demand, reducing storage costs and waste. Just-in-Case (JIC) strategy maintains extra inventory as a buffer against supply chain disruptions, ensuring operational continuity during uncertainties. Businesses must analyze demand variability and supply chain reliability to balance efficiency and risk between JIT and JIC approaches.

Core Principles of Just-in-Time Inventory Management

Just-in-time (JIT) inventory management emphasizes minimizing stock levels by aligning production schedules closely with demand forecasts, thereby reducing holding costs and waste. Core principles include continuous improvement, strong supplier relationships, and precise demand forecasting to ensure materials arrive exactly when needed. This approach contrasts with just-in-case strategies that prioritize inventory buffer stocks for risk mitigation.

Key Features of Just-in-Case Inventory Strategies

Just-in-case inventory strategies prioritize maintaining high stock levels to mitigate risks from supply chain disruptions, demand fluctuations, and unexpected emergencies. This approach emphasizes safety stock, strategic reserves, and buffer inventory to ensure continuous production and customer satisfaction. Companies using just-in-case methods often face higher holding costs but gain resilience and flexibility in uncertain market conditions.

Benefits of Adopting Just-in-Time Practices

Just-in-time (JIT) practices enhance operational efficiency by minimizing inventory holding costs and reducing waste, leading to significant cost savings for businesses. This approach improves cash flow management and increases responsiveness to market demand, enabling companies to adapt quickly to customer needs and reduce lead times. Implementing JIT fosters stronger supplier relationships through streamlined supply chains, contributing to overall improved productivity and competitiveness.

Risks and Limitations of Just-in-Case Approaches

Just-in-case inventory strategies involve maintaining excess stock to mitigate supply chain disruptions, which can lead to increased holding costs and decreased cash flow efficiency. This approach risks inventory obsolescence, especially in industries with rapid product innovation or fluctuating demand patterns. Companies must balance the safety net of just-in-case systems against potential financial strain and reduced agility in responding to market changes.

Impact of Supply Chain Disruptions on Inventory Models

Just-in-time (JIT) inventory models minimize holding costs by receiving goods only as needed, but are highly vulnerable to supply chain disruptions, leading to production delays and stockouts. Just-in-case (JIC) strategies maintain higher inventory levels to buffer against uncertainties, increasing carrying costs but enhancing resilience to supply interruptions. The choice between JIT and JIC depends on the volatility of the supply chain, with industries facing frequent disruptions favoring JIC for risk mitigation despite increased capital tied up in inventory.

Cost Efficiency: JIT vs JIC in Modern Businesses

Just-in-time (JIT) inventory systems minimize carrying costs by aligning production schedules closely with demand, reducing waste and capital tied up in stock. Just-in-case (JIC) strategies incur higher storage expenses and potential obsolescence but offer protection against supply chain disruptions and demand spikes. Modern businesses weigh JIT's cost efficiency against JIC's risk mitigation to optimize operational resilience and financial performance.

Flexibility and Responsiveness in Inventory Planning

Just-in-time (JIT) inventory planning maximizes responsiveness by reducing stock levels and enabling rapid adaptation to demand fluctuations, minimizing waste and holding costs. Just-in-case (JIC) inventory emphasizes flexibility through maintaining buffer stock to safeguard against supply chain disruptions and demand spikes, ensuring continuous production flow. Businesses balance JIT and JIC strategies to optimize inventory responsiveness and adapt to market volatility effectively.

Industry Examples: JIT and JIC in Action

Toyota exemplifies Just-In-Time (JIT) manufacturing by minimizing inventory and delivering parts precisely when needed, reducing waste and boosting efficiency. Conversely, Procter & Gamble employs Just-In-Case (JIC) strategies by maintaining large safety stock levels to prevent stockouts during demand spikes or supply disruptions. This contrast illustrates how automotive industries favor JIT for lean production while consumer goods sectors rely on JIC for supply chain resilience.

Choosing the Right Inventory Strategy for Your Business

Choosing the right inventory strategy, whether just-in-time (JIT) or just-in-case (JIC), depends on business size, market demand, and supply chain reliability. JIT minimizes inventory costs and reduces waste by receiving goods only as needed, benefiting industries with stable supply lines and predictable demand. JIC maintains buffer stock to guard against supply disruptions and demand spikes, making it ideal for businesses facing uncertain markets or longer lead times.

just-in-time vs just-in-case Infographic

difterm.com

difterm.com