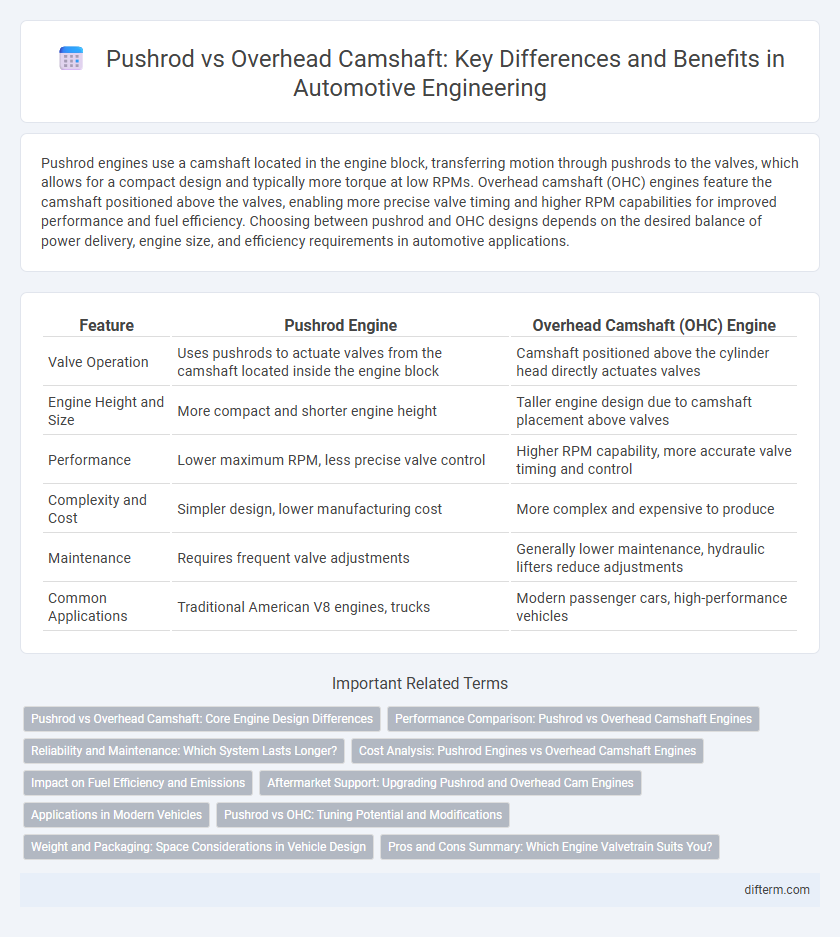

Pushrod engines use a camshaft located in the engine block, transferring motion through pushrods to the valves, which allows for a compact design and typically more torque at low RPMs. Overhead camshaft (OHC) engines feature the camshaft positioned above the valves, enabling more precise valve timing and higher RPM capabilities for improved performance and fuel efficiency. Choosing between pushrod and OHC designs depends on the desired balance of power delivery, engine size, and efficiency requirements in automotive applications.

Table of Comparison

| Feature | Pushrod Engine | Overhead Camshaft (OHC) Engine |

|---|---|---|

| Valve Operation | Uses pushrods to actuate valves from the camshaft located inside the engine block | Camshaft positioned above the cylinder head directly actuates valves |

| Engine Height and Size | More compact and shorter engine height | Taller engine design due to camshaft placement above valves |

| Performance | Lower maximum RPM, less precise valve control | Higher RPM capability, more accurate valve timing and control |

| Complexity and Cost | Simpler design, lower manufacturing cost | More complex and expensive to produce |

| Maintenance | Requires frequent valve adjustments | Generally lower maintenance, hydraulic lifters reduce adjustments |

| Common Applications | Traditional American V8 engines, trucks | Modern passenger cars, high-performance vehicles |

Pushrod vs Overhead Camshaft: Core Engine Design Differences

Pushrod engines feature a camshaft located within the engine block that uses pushrods to actuate the valves, resulting in a more compact and simpler design compared to overhead camshaft (OHC) engines. Overhead camshaft engines position the camshaft(s) directly above the valves, allowing for more precise valve timing and higher engine speeds. These fundamental architectural differences influence engine performance, complexity, and packaging, with pushrod engines often favored for torque and durability while OHC designs excel in efficiency and RPM potential.

Performance Comparison: Pushrod vs Overhead Camshaft Engines

Pushrod engines deliver robust low-end torque due to shorter valvetrain components, making them ideal for heavy-duty and muscle cars. Overhead camshaft (OHC) engines provide superior high-RPM performance and efficiency by allowing precise valve timing and reduced valvetrain mass. The OHC design often results in better fuel economy and power output, favored in sports and modern vehicles for enhanced driving dynamics.

Reliability and Maintenance: Which System Lasts Longer?

Pushrod engines generally offer greater long-term reliability due to their simpler design and fewer moving parts, resulting in reduced wear and easier maintenance. Overhead camshaft (OHC) systems deliver improved performance but often require more frequent adjustments and higher maintenance costs because of increased mechanical complexity. In terms of longevity, pushrod designs typically last longer with routine care, making them favored in applications where durability is prioritized over high-rev performance.

Cost Analysis: Pushrod Engines vs Overhead Camshaft Engines

Pushrod engines typically offer lower manufacturing and maintenance costs due to their simpler design and fewer moving parts, making them more budget-friendly for entry-level vehicles and trucks. Overhead camshaft (OHC) engines, while more complex and expensive to produce, provide improved performance and fuel efficiency, which can result in long-term savings on fuel and decreased emissions-related expenses. Cost analysis should balance initial expenses with potential maintenance and operational savings, with pushrod engines being cost-effective upfront, whereas OHC engines often deliver greater value over the vehicle's lifespan.

Impact on Fuel Efficiency and Emissions

Pushrod engines typically exhibit lower fuel efficiency and higher emissions due to their less precise valve timing and increased internal friction compared to overhead camshaft (OHC) designs. Overhead camshafts enable more accurate control over valve operation, improving combustion efficiency and reducing fuel consumption and harmful emissions. Consequently, OHC technology is favored in modern automotive engineering to meet stringent environmental regulations and enhance overall engine performance.

Aftermarket Support: Upgrading Pushrod and Overhead Cam Engines

Aftermarket support for pushrod engines is robust, offering numerous upgrade options such as high-performance camshafts, rocker arms, and valve springs that enhance durability and power output. Overhead camshaft (OHC) engines benefit from advanced aftermarket components including lightweight camshafts, adjustable cam gears, and electronic timing controllers for precise valve timing optimization. Both engine types have wide availability of performance parts, but OHC engines often see more innovation due to their prevalence in modern vehicles and greater potential for high-rev tuning.

Applications in Modern Vehicles

Pushrod engines are commonly used in muscle cars and trucks due to their compact design and high torque output at low RPMs, making them ideal for towing and heavy-duty applications. Overhead camshaft (OHC) engines dominate modern passenger cars and performance vehicles because they allow for higher engine speeds and improved fuel efficiency through precise valve timing. Advanced OHC designs, including dual overhead camshafts, enhance power delivery and emissions control, supporting stricter environmental regulations in current automotive markets.

Pushrod vs OHC: Tuning Potential and Modifications

Pushrod engines offer simpler valvetrain designs, allowing for easier and cost-effective modifications such as camshaft swaps and valve upgrades, ideal for straightforward tuning. Overhead camshaft (OHC) engines provide better high-RPM performance and precise valve timing adjustments due to their direct cam-to-valve actuation, enabling advanced tuning techniques like variable valve timing and aggressive cam profiles. While pushrods excel in low-end torque tuning, OHC engines dominate in high-performance modifications requiring higher rev limits and improved airflow dynamics.

Weight and Packaging: Space Considerations in Vehicle Design

Pushrod engines are typically more compact and lighter due to fewer moving parts and reduced valvetrain complexity, offering improved packaging flexibility in tight engine bays. Overhead camshaft (OHC) engines generally require additional space for camshafts positioned above the valves, resulting in increased engine height and weight. These differences heavily influence vehicle design choices, especially in models prioritizing efficient space utilization and weight reduction.

Pros and Cons Summary: Which Engine Valvetrain Suits You?

Pushrod engines offer a compact design and lower manufacturing costs, making them ideal for muscle cars and trucks where torque and simplicity are prioritized, but they tend to have lower RPM ceilings and less efficient valve timing compared to overhead camshaft (OHC) engines. Overhead camshaft engines provide better high-RPM performance, improved fuel efficiency, and more precise valve control, suited for high-performance and modern passenger vehicles, though they come with increased complexity and manufacturing costs. Choosing between pushrod and OHC valvetrains depends on the balance of performance needs, cost constraints, and maintenance preferences.

Pushrod vs Overhead Camshaft Infographic

difterm.com

difterm.com