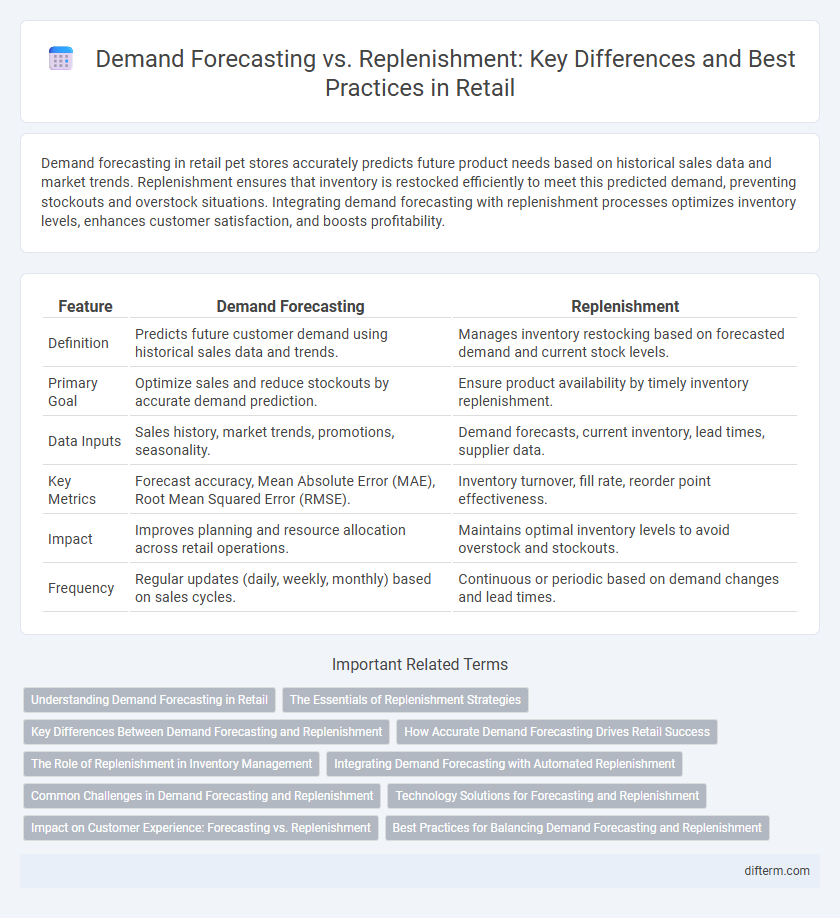

Demand forecasting in retail pet stores accurately predicts future product needs based on historical sales data and market trends. Replenishment ensures that inventory is restocked efficiently to meet this predicted demand, preventing stockouts and overstock situations. Integrating demand forecasting with replenishment processes optimizes inventory levels, enhances customer satisfaction, and boosts profitability.

Table of Comparison

| Feature | Demand Forecasting | Replenishment |

|---|---|---|

| Definition | Predicts future customer demand using historical sales data and trends. | Manages inventory restocking based on forecasted demand and current stock levels. |

| Primary Goal | Optimize sales and reduce stockouts by accurate demand prediction. | Ensure product availability by timely inventory replenishment. |

| Data Inputs | Sales history, market trends, promotions, seasonality. | Demand forecasts, current inventory, lead times, supplier data. |

| Key Metrics | Forecast accuracy, Mean Absolute Error (MAE), Root Mean Squared Error (RMSE). | Inventory turnover, fill rate, reorder point effectiveness. |

| Impact | Improves planning and resource allocation across retail operations. | Maintains optimal inventory levels to avoid overstock and stockouts. |

| Frequency | Regular updates (daily, weekly, monthly) based on sales cycles. | Continuous or periodic based on demand changes and lead times. |

Understanding Demand Forecasting in Retail

Demand forecasting in retail involves analyzing historical sales data, market trends, and customer behavior to predict future product demand accurately. Advanced algorithms and machine learning models enhance forecasting precision, enabling retailers to optimize inventory levels and reduce stockouts or overstock situations. Accurate demand forecasting directly impacts replenishment efficiency by informing timely restocking decisions that align with anticipated consumer needs.

The Essentials of Replenishment Strategies

Effective replenishment strategies rely on accurate demand forecasting to maintain optimal inventory levels, prevent stockouts, and reduce excess holding costs. Key elements include lead time analysis, safety stock calculation, and order quantity optimization to align supply with fluctuating consumer demand. Integrating real-time sales data with historical trends ensures responsive and efficient inventory management in retail environments.

Key Differences Between Demand Forecasting and Replenishment

Demand forecasting involves predicting future customer demand using historical sales data, seasonal trends, and market analysis to optimize inventory levels. Replenishment focuses on the process of restocking inventory based on demand forecasts and actual sales to maintain product availability and avoid stockouts. The key difference lies in demand forecasting being a predictive analytical task, while replenishment is an operational execution driven by those forecasts.

How Accurate Demand Forecasting Drives Retail Success

Accurate demand forecasting enables retailers to optimize inventory levels, reducing stockouts and overstock situations that directly impact sales and profitability. By analyzing historical sales data, market trends, and consumer behavior, retailers can anticipate customer demand with greater precision, ensuring replenishment aligns with actual needs. Effective forecasting minimizes holding costs and enhances customer satisfaction, driving overall retail success through improved operational efficiency.

The Role of Replenishment in Inventory Management

Replenishment plays a critical role in inventory management by ensuring optimal stock levels are maintained to meet customer demand without overstocking or stockouts. It leverages demand forecasting data to trigger timely restocking, balancing supply chain efficiency and customer satisfaction. Effective replenishment strategies reduce carrying costs and improve turnover rates, enhancing overall retail profitability.

Integrating Demand Forecasting with Automated Replenishment

Integrating demand forecasting with automated replenishment streamlines inventory management by aligning stock levels directly with predicted consumer demand patterns. Advanced algorithms analyze historical sales data and market trends to generate accurate demand forecasts, which trigger precise replenishment orders in real time. This integration reduces stockouts and overstock situations, optimizing supply chain efficiency and enhancing customer satisfaction in retail operations.

Common Challenges in Demand Forecasting and Replenishment

Demand forecasting and replenishment in retail face common challenges such as inaccurate sales data, fluctuating consumer behavior, and supply chain disruptions that complicate inventory management. Limited visibility into real-time demand and external factors like seasonality or promotions often result in stockouts or overstock situations. Implementing advanced analytics and machine learning models enhances forecast accuracy and optimizes replenishment schedules to mitigate these challenges.

Technology Solutions for Forecasting and Replenishment

Advanced demand forecasting leverages machine learning algorithms and AI-driven predictive analytics to analyze historical sales data, seasonality, and market trends with high accuracy. Replenishment technology integrates real-time inventory tracking and automated ordering systems, ensuring optimal stock levels and reducing stockouts or overstock situations. Cloud-based platforms and IoT sensors enhance synchronization between demand forecasts and replenishment actions, improving supply chain responsiveness and operational efficiency.

Impact on Customer Experience: Forecasting vs. Replenishment

Accurate demand forecasting enables retailers to anticipate customer needs, ensuring product availability and reducing stockouts that can frustrate shoppers. Effective replenishment processes translate these forecasts into timely inventory restocking, minimizing delays and enhancing the shopping experience. Together, precise forecasting and efficient replenishment drive higher customer satisfaction by maintaining optimal product levels and avoiding lost sales.

Best Practices for Balancing Demand Forecasting and Replenishment

Accurate demand forecasting leverages historical sales data, seasonality trends, and market analysis to predict future product needs, enhancing inventory planning. Effective replenishment strategies rely on these forecasts to maintain optimal stock levels, preventing both stockouts and overstock situations. Integrating real-time sales tracking with automated reorder systems establishes a dynamic balance, improving customer satisfaction and reducing holding costs.

Demand Forecasting vs Replenishment Infographic

difterm.com

difterm.com