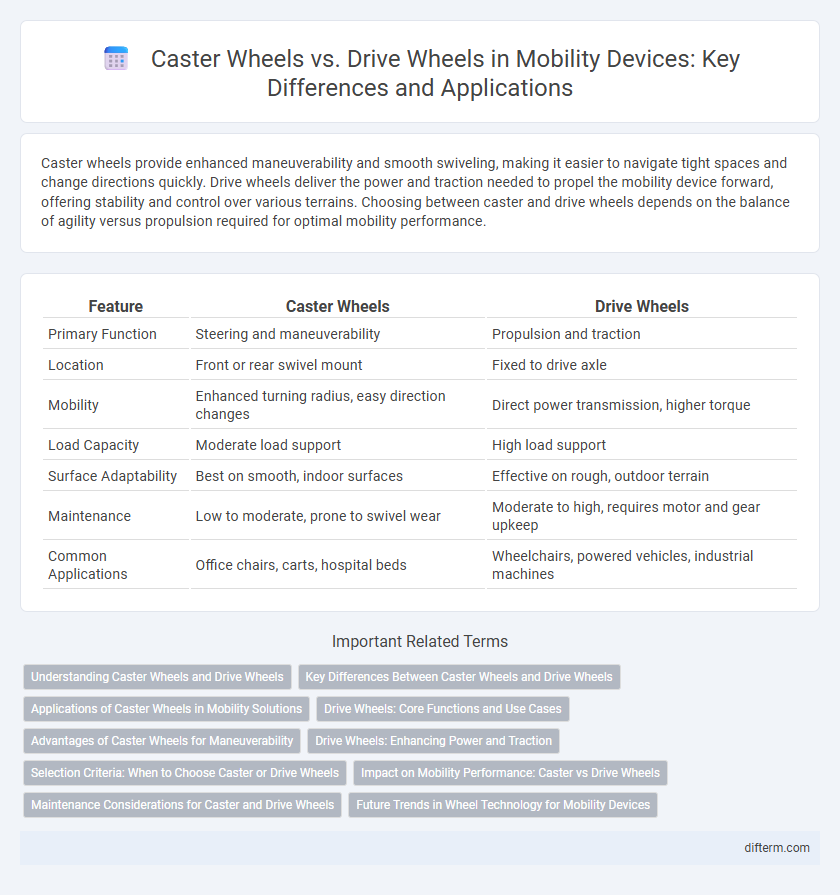

Caster wheels provide enhanced maneuverability and smooth swiveling, making it easier to navigate tight spaces and change directions quickly. Drive wheels deliver the power and traction needed to propel the mobility device forward, offering stability and control over various terrains. Choosing between caster and drive wheels depends on the balance of agility versus propulsion required for optimal mobility performance.

Table of Comparison

| Feature | Caster Wheels | Drive Wheels |

|---|---|---|

| Primary Function | Steering and maneuverability | Propulsion and traction |

| Location | Front or rear swivel mount | Fixed to drive axle |

| Mobility | Enhanced turning radius, easy direction changes | Direct power transmission, higher torque |

| Load Capacity | Moderate load support | High load support |

| Surface Adaptability | Best on smooth, indoor surfaces | Effective on rough, outdoor terrain |

| Maintenance | Low to moderate, prone to swivel wear | Moderate to high, requires motor and gear upkeep |

| Common Applications | Office chairs, carts, hospital beds | Wheelchairs, powered vehicles, industrial machines |

Understanding Caster Wheels and Drive Wheels

Caster wheels provide multidirectional movement and are typically mounted on the front or rear of a mobility device, allowing for smooth steering and maneuverability. Drive wheels are larger, powered wheels usually located centrally or at the rear, responsible for propulsion and traction on various surfaces. Understanding the distinct roles of caster wheels and drive wheels enhances the selection of mobility equipment tailored to specific terrain and user needs.

Key Differences Between Caster Wheels and Drive Wheels

Caster wheels provide smooth directional movement and are designed to swivel freely, allowing easy navigation and turning. Drive wheels generate propulsion force and are powered by motors or human effort, delivering traction and stability necessary for forward or backward motion. Understanding the roles of caster wheels and drive wheels is critical in optimizing mobility devices for performance and maneuverability.

Applications of Caster Wheels in Mobility Solutions

Caster wheels provide superior maneuverability and swivel capabilities, making them ideal for applications in mobility aids such as wheelchairs, hospital beds, and medical equipment carts. Their ability to rotate 360 degrees enhances navigation in tight spaces and facilitates smooth directional changes, critical for indoor environments. Often constructed from durable materials like polyurethane or rubber, caster wheels ensure stability and noise reduction while supporting various weight capacities essential for different mobility solutions.

Drive Wheels: Core Functions and Use Cases

Drive wheels are the primary wheels responsible for propelling a wheelchair or mobility device forward, providing traction and maneuverability on various surfaces. They are typically larger in diameter than caster wheels, enabling better control, speed, and efficiency over uneven terrain and inclines. Common use cases for drive wheels include outdoor mobility, navigating ramps, and facilitating independent movement in both manual and powered wheelchairs.

Advantages of Caster Wheels for Maneuverability

Caster wheels enhance maneuverability by allowing smooth 360-degree rotation, enabling tight turns and precise directional changes in confined spaces. Their ability to swivel reduces friction and effort needed to navigate complex environments, making them ideal for mobility aids and equipment that require high agility. Compared to drive wheels, caster wheels provide superior control and flexibility, improving overall user experience and efficiency.

Drive Wheels: Enhancing Power and Traction

Drive wheels provide superior power transfer and traction essential for effective mobility on various terrains. Equipped with robust motors and treads, drive wheels enable enhanced control and stability, particularly in outdoor or uneven environments. Their design optimizes energy efficiency while ensuring smooth, reliable propulsion for powered wheelchairs and mobility devices.

Selection Criteria: When to Choose Caster or Drive Wheels

Selecting caster wheels is ideal for applications requiring high maneuverability and easy swiveling, such as in tight spaces or when frequent changes in direction are necessary. Drive wheels should be chosen for situations demanding strong traction and propulsion, especially on uneven or inclined surfaces where powered movement is essential. Evaluating load capacity, floor type, and mobility needs ensures optimal performance and longevity in mobility solutions.

Impact on Mobility Performance: Caster vs Drive Wheels

Drive wheels provide primary propulsion and traction, directly influencing acceleration, speed, and maneuverability on varied terrains. Caster wheels enhance stability and directional control, allowing smoother turns and improved handling, especially in tight spaces. The combination of drive wheels for power and caster wheels for balance optimizes overall mobility performance, ensuring agility and efficiency in movement.

Maintenance Considerations for Caster and Drive Wheels

Maintenance considerations for caster wheels mainly involve regular inspection for debris buildup, lubrication of swivel bearings, and checking for uneven wear to ensure smooth and quiet operation. Drive wheels require more intensive upkeep, including motor maintenance, tire condition checks, and alignment to maintain traction and power efficiency in mobility devices. Both wheel types demand periodic cleaning and timely replacement to maximize durability and overall mobility performance.

Future Trends in Wheel Technology for Mobility Devices

Advancements in wheel technology for mobility devices focus on integrating smart sensors into caster and drive wheels to improve real-time terrain adaptation and enhance user stability. Future trends emphasize lightweight, durable materials like carbon fiber composites in drive wheels and omnidirectional capabilities in caster wheels to increase maneuverability in confined spaces. Energy-harvesting mechanisms embedded in both wheel types are being developed to extend battery life by converting kinetic energy into electrical power during movement.

Caster wheels vs Drive wheels Infographic

difterm.com

difterm.com