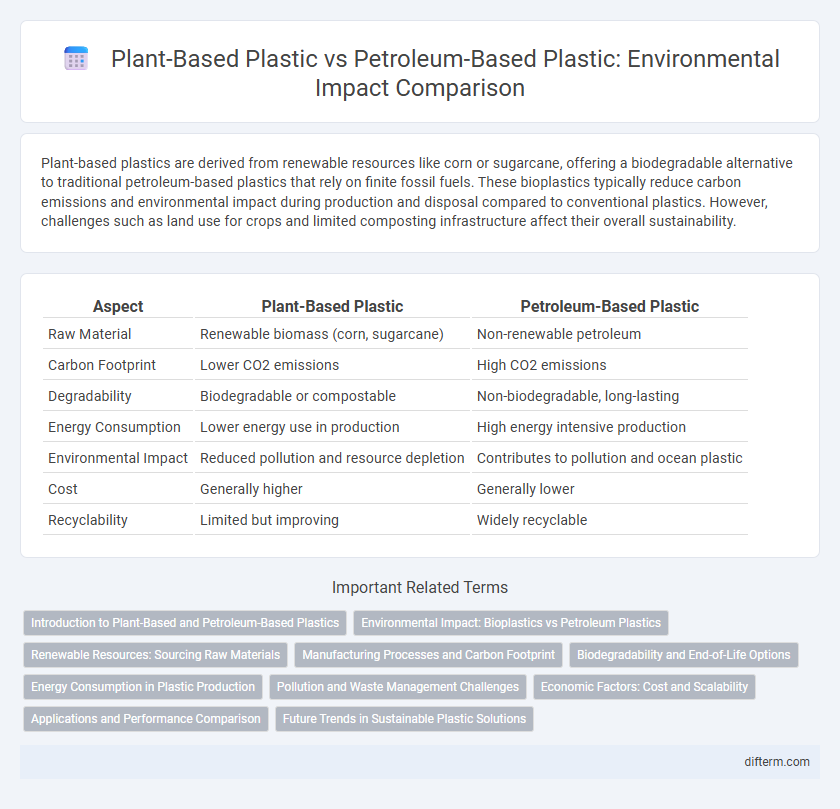

Plant-based plastics are derived from renewable resources like corn or sugarcane, offering a biodegradable alternative to traditional petroleum-based plastics that rely on finite fossil fuels. These bioplastics typically reduce carbon emissions and environmental impact during production and disposal compared to conventional plastics. However, challenges such as land use for crops and limited composting infrastructure affect their overall sustainability.

Table of Comparison

| Aspect | Plant-Based Plastic | Petroleum-Based Plastic |

|---|---|---|

| Raw Material | Renewable biomass (corn, sugarcane) | Non-renewable petroleum |

| Carbon Footprint | Lower CO2 emissions | High CO2 emissions |

| Degradability | Biodegradable or compostable | Non-biodegradable, long-lasting |

| Energy Consumption | Lower energy use in production | High energy intensive production |

| Environmental Impact | Reduced pollution and resource depletion | Contributes to pollution and ocean plastic |

| Cost | Generally higher | Generally lower |

| Recyclability | Limited but improving | Widely recyclable |

Introduction to Plant-Based and Petroleum-Based Plastics

Plant-based plastics, derived from renewable biomass such as corn, sugarcane, and cellulose, offer a sustainable alternative to traditional petroleum-based plastics, which are produced from finite fossil fuels like crude oil and natural gas. These bioplastics typically reduce carbon emissions during production and may biodegrade under specific conditions, contrasting with petroleum plastics that persist in the environment for centuries and contribute significantly to pollution. Understanding the chemical composition and lifecycle of both types is crucial for assessing their environmental impact and potential in reducing plastic waste globally.

Environmental Impact: Bioplastics vs Petroleum Plastics

Plant-based plastics, or bioplastics, significantly reduce carbon emissions by utilizing renewable biomass instead of fossil fuels, leading to lower greenhouse gas production throughout their lifecycle. Petroleum-based plastics contribute heavily to pollution and resource depletion due to their reliance on non-renewable oil extraction and long degradation periods causing persistent environmental contamination. Bioplastics generally offer enhanced biodegradability and compostability, which mitigates plastic waste accumulation and reduces landfill burden compared to conventional petroleum-based plastics.

Renewable Resources: Sourcing Raw Materials

Plant-based plastics derive raw materials from renewable resources such as corn, sugarcane, and cellulose, reducing dependence on finite fossil fuels. Petroleum-based plastics rely on crude oil and natural gas, which are non-renewable and contribute to environmental degradation during extraction. Utilizing renewable biomass for plant-based plastics supports sustainability and decreased carbon footprint in the manufacturing process.

Manufacturing Processes and Carbon Footprint

Plant-based plastics are produced through fermentation of renewable biomass such as corn starch, sugarcane, or cellulose, resulting in significantly lower greenhouse gas emissions compared to petroleum-based plastics manufactured through energy-intensive refining and polymerization of fossil fuels. The carbon footprint of plant-based plastics is reduced due to carbon sequestration during crop growth and the potential for biodegradability, whereas petroleum-based plastics contribute to higher CO2 emissions throughout their lifecycle, including extraction, processing, and disposal stages. Advances in biopolymer technology and sustainable agriculture further optimize the environmental impact and energy efficiency of plant-based plastic manufacturing.

Biodegradability and End-of-Life Options

Plant-based plastics, derived from renewable biomass such as corn starch or sugarcane, often exhibit enhanced biodegradability compared to petroleum-based plastics, breaking down more readily in industrial composting facilities. These bioplastics offer diverse end-of-life options including composting, anaerobic digestion, and potential recycling, which can reduce landfill dependence and decrease environmental pollution. In contrast, petroleum-based plastics tend to persist in ecosystems for centuries due to their resistance to microbial degradation, limiting their end-of-life management primarily to recycling or landfilling.

Energy Consumption in Plastic Production

Plant-based plastics generally require less energy to produce compared to petroleum-based plastics, as they often utilize renewable resources such as corn or sugarcane, which capture carbon dioxide during growth. The production of petroleum-based plastics involves energy-intensive processes including extraction, refining, and polymerization of crude oil, leading to higher overall energy consumption and greenhouse gas emissions. Transitioning to bio-based plastics can reduce the carbon footprint associated with plastic manufacturing, although factors like agricultural inputs and land use must also be considered for accurate energy consumption assessments.

Pollution and Waste Management Challenges

Plant-based plastics generate less toxic pollution during production compared to petroleum-based plastics, but both types contribute significantly to environmental waste due to limited biodegradability and recycling infrastructure. Petroleum-based plastics persist in ecosystems for hundreds of years, releasing harmful microplastics and chemicals, whereas plant-based plastics often require industrial composting facilities for proper degradation, which remain scarce. Effective waste management solutions must address the contamination and sorting challenges posed by the mixed use of these plastics to reduce landfill accumulation and marine pollution.

Economic Factors: Cost and Scalability

Plant-based plastics often incur higher initial production costs due to the expense of raw materials like corn or sugarcane, which can limit scalability compared to petroleum-based plastics derived from abundant fossil fuels. Economies of scale currently favor petroleum-based plastics, enabling mass production at lower prices, while plant-based alternatives face challenges in achieving cost parity due to agricultural variability and processing complexity. Investment in bioplastic technology and increased demand can drive down prices, but widespread adoption depends on overcoming infrastructure limitations and balancing environmental benefits with economic feasibility.

Applications and Performance Comparison

Plant-based plastics, derived from renewable resources like corn starch and sugarcane, are increasingly used in packaging, agriculture, and consumer products due to their biodegradability and reduced carbon footprint. Petroleum-based plastics, favored in automotive, construction, and electronics industries, offer superior durability, heat resistance, and mechanical strength but contribute significantly to environmental pollution. While bioplastics excel in compostability and reducing fossil fuel dependency, petroleum plastics outperform in versatility and long-term performance under harsh conditions.

Future Trends in Sustainable Plastic Solutions

Plant-based plastics, derived from renewable biomass such as corn starch and sugarcane, are rapidly advancing due to their biodegradability and lower carbon footprint compared to petroleum-based plastics, which are sourced from finite fossil fuels and contribute significantly to greenhouse gas emissions. Innovations in biopolymer technology and improved composting infrastructure are expected to enhance the scalability and environmental benefits of plant-based plastics, driving a shift in the global plastics market by 2030. Industry forecasts predict that increased consumer demand and regulatory pressure will accelerate the transition towards sustainable plastic solutions, reducing dependence on conventional petroleum-based plastics and fostering a circular economy.

plant-based plastic vs petroleum-based plastic Infographic

difterm.com

difterm.com