Lost-wax casting offers superior precision and intricate detail, making it ideal for creating complex art sculptures with smooth surfaces. Sand casting, while more cost-effective and suitable for larger-scale pieces, often results in rougher textures and less refined finishes. Artists seeking high-quality, detailed metalworks typically prefer lost-wax casting for its ability to capture fine artistic expressions.

Table of Comparison

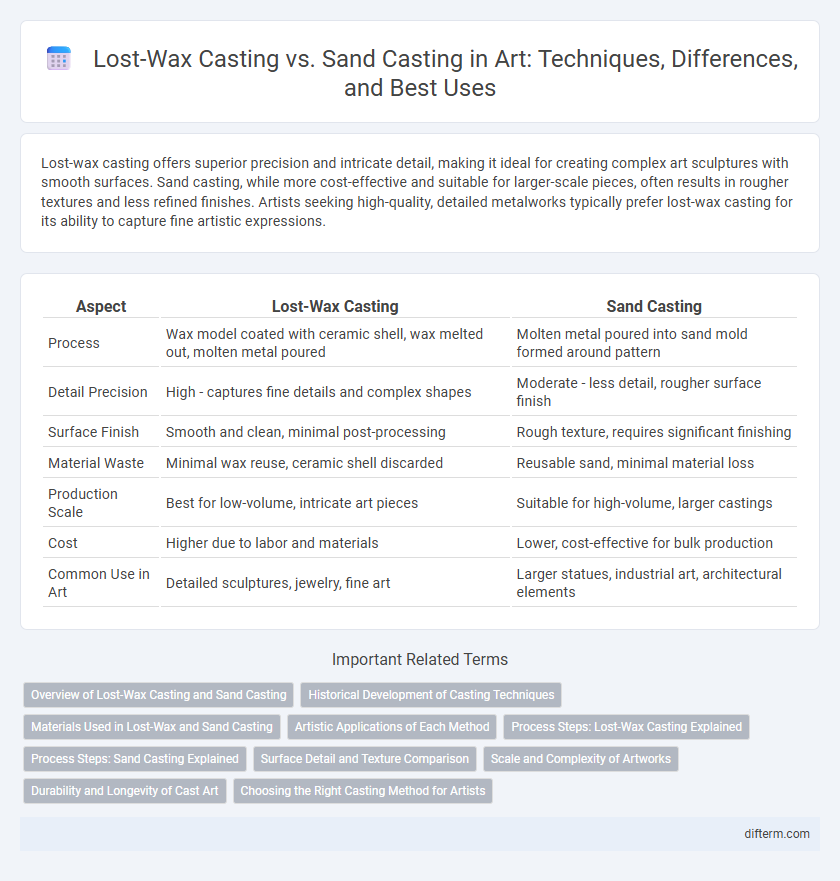

| Aspect | Lost-Wax Casting | Sand Casting |

|---|---|---|

| Process | Wax model coated with ceramic shell, wax melted out, molten metal poured | Molten metal poured into sand mold formed around pattern |

| Detail Precision | High - captures fine details and complex shapes | Moderate - less detail, rougher surface finish |

| Surface Finish | Smooth and clean, minimal post-processing | Rough texture, requires significant finishing |

| Material Waste | Minimal wax reuse, ceramic shell discarded | Reusable sand, minimal material loss |

| Production Scale | Best for low-volume, intricate art pieces | Suitable for high-volume, larger castings |

| Cost | Higher due to labor and materials | Lower, cost-effective for bulk production |

| Common Use in Art | Detailed sculptures, jewelry, fine art | Larger statues, industrial art, architectural elements |

Overview of Lost-Wax Casting and Sand Casting

Lost-wax casting, also known as investment casting, involves creating a detailed wax model coated with refractory material to form a mold, which is then melted away to leave a cavity for molten metal. Sand casting uses a sand-based mold formed around a pattern, where the sand provides thermal resistance and shape retention during metal pouring. Lost-wax casting enables intricate designs and fine surface detail, while sand casting is typically used for larger, less detailed metal parts due to its cost-effectiveness and flexibility.

Historical Development of Casting Techniques

Lost-wax casting dates back over 5,000 years, originating in ancient civilizations like Mesopotamia and Egypt, enabling intricate metal artworks and sculptures through precise wax mold creations. Sand casting, with roots in Roman and Chinese metallurgy around 2,000 years ago, allowed for larger, more functional metal objects using reusable sand molds, promoting industrial-scale production. Both techniques significantly influenced the evolution of metalworking in art, with lost-wax excelling in detail and sand casting advancing mass production.

Materials Used in Lost-Wax and Sand Casting

Lost-wax casting primarily uses wax to create detailed molds, which are then encased in a ceramic or plaster shell before melting the wax away, allowing molten metal such as bronze, gold, or silver to fill the cavity. Sand casting utilizes a mixture of sand, clay, and water to form a reusable mold, suitable for metals like iron, aluminum, and brass but less capable of capturing fine details compared to lost-wax casting. The choice of materials in lost-wax casting enables superior precision and surface finish, while sand casting offers versatility and cost-effectiveness for larger or simpler metal artworks.

Artistic Applications of Each Method

Lost-wax casting offers precise detail and smooth finishes, making it ideal for intricate sculptures and fine art pieces that require high fidelity and complex designs. Sand casting excels in producing larger, more robust forms with textured surfaces, often favored for monumental outdoor installations and bold, raw aesthetic expressions. Each method uniquely supports artistic expression by balancing detail resolution and material versatility to suit diverse creative visions.

Process Steps: Lost-Wax Casting Explained

Lost-wax casting involves creating a detailed wax model which is then coated in a refractory ceramic material to form a mold; once hardened, the wax is melted away, leaving a cavity for molten metal. This process allows for high precision and intricate designs, commonly used in art bronze sculptures and jewelry making. The final step involves breaking the ceramic mold to reveal the metal casting, which is then cleaned and polished to achieve the desired artistic finish.

Process Steps: Sand Casting Explained

Sand casting involves creating a mold by compacting sand around a pattern, which is then removed to form a cavity for molten metal. The key process steps include preparing the sand mold, pouring molten metal into the mold cavity, and allowing the metal to cool and solidify before removing the sand. This technique enables the production of complex metal shapes with detailed surface textures while maintaining cost efficiency for both small and large production runs.

Surface Detail and Texture Comparison

Lost-wax casting produces intricate surface details with smooth, refined textures ideal for fine art sculptures, capturing delicate patterns and sharp edges. Sand casting typically results in rougher surfaces with more granular textures, requiring extensive finishing for detailed artwork. Artists favor lost-wax casting for precision and fidelity in complex designs, while sand casting suits larger, less detailed pieces.

Scale and Complexity of Artworks

Lost-wax casting allows for the creation of highly detailed and complex sculptures, making it ideal for intricate artworks and smaller-scale pieces with fine textures. Sand casting is better suited for larger-scale artworks that require robust and less detailed forms, offering versatility in size but limited precision in fine details. Artists often choose lost-wax casting for elaborate designs and sand casting for monumental or bulkier art installations.

Durability and Longevity of Cast Art

Lost-wax casting produces highly detailed and durable art pieces by creating precise molds from wax patterns, resulting in fine textures and intricate shapes that withstand aging and environmental factors. Sand casting, while more cost-effective, tends to have a rougher surface finish and is less resilient to wear over time due to its coarser mold material. Artists seeking longevity and preservation of delicate features often prefer lost-wax casting for sculptures intended to endure through generations.

Choosing the Right Casting Method for Artists

Lost-wax casting offers artists exquisite detail and smooth finishes ideal for intricate sculptures, while sand casting provides a cost-effective option for larger, less detailed works. Understanding the complexity and size of the artwork helps determine the ideal technique, as lost-wax suits fine art pieces and sand casting serves practical, robust designs. Material selection, desired texture, and budget constraints also critically influence the choice between these casting methods.

Lost-wax casting vs Sand casting Infographic

difterm.com

difterm.com