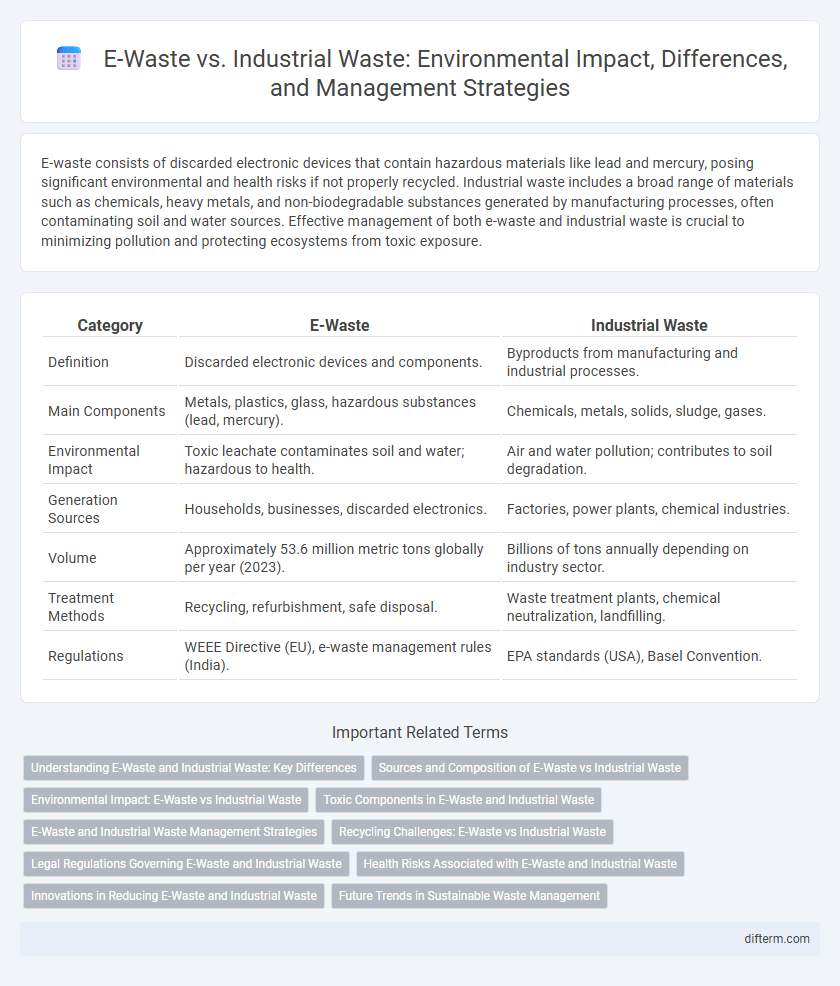

E-waste consists of discarded electronic devices that contain hazardous materials like lead and mercury, posing significant environmental and health risks if not properly recycled. Industrial waste includes a broad range of materials such as chemicals, heavy metals, and non-biodegradable substances generated by manufacturing processes, often contaminating soil and water sources. Effective management of both e-waste and industrial waste is crucial to minimizing pollution and protecting ecosystems from toxic exposure.

Table of Comparison

| Category | E-Waste | Industrial Waste |

|---|---|---|

| Definition | Discarded electronic devices and components. | Byproducts from manufacturing and industrial processes. |

| Main Components | Metals, plastics, glass, hazardous substances (lead, mercury). | Chemicals, metals, solids, sludge, gases. |

| Environmental Impact | Toxic leachate contaminates soil and water; hazardous to health. | Air and water pollution; contributes to soil degradation. |

| Generation Sources | Households, businesses, discarded electronics. | Factories, power plants, chemical industries. |

| Volume | Approximately 53.6 million metric tons globally per year (2023). | Billions of tons annually depending on industry sector. |

| Treatment Methods | Recycling, refurbishment, safe disposal. | Waste treatment plants, chemical neutralization, landfilling. |

| Regulations | WEEE Directive (EU), e-waste management rules (India). | EPA standards (USA), Basel Convention. |

Understanding E-Waste and Industrial Waste: Key Differences

E-waste consists of discarded electronic devices such as smartphones, computers, and TVs, characterized by hazardous materials like lead, mercury, and cadmium that pose significant environmental and health risks if improperly disposed of. Industrial waste includes by-products from manufacturing processes, often consisting of chemicals, heavy metals, and non-biodegradable substances requiring specialized treatment to prevent soil and water contamination. Understanding these differences is critical for implementing targeted waste management practices that mitigate pollution and promote sustainable resource recovery.

Sources and Composition of E-Waste vs Industrial Waste

E-waste primarily originates from discarded electronic devices such as computers, smartphones, and televisions, consisting of hazardous materials like heavy metals and plastic components. Industrial waste stems from manufacturing processes and factories, comprising chemical by-products, metals, and non-biodegradable substances. The complex composition of e-waste demands specialized recycling methods to mitigate toxic exposure, whereas industrial waste management focuses on treating chemical pollutants and solid residues.

Environmental Impact: E-Waste vs Industrial Waste

E-waste contains hazardous materials such as lead, mercury, and cadmium, which pose significant risks to soil and water contamination if improperly disposed. Industrial waste often includes heavy metals, toxic chemicals, and non-biodegradable materials that can cause extensive air, water, and land pollution affecting biodiversity and human health. Proper management and recycling practices are crucial to minimizing the environmental impact of both e-waste and industrial waste streams.

Toxic Components in E-Waste and Industrial Waste

E-waste contains hazardous substances such as lead, mercury, cadmium, and brominated flame retardants, which pose significant risks to soil and water quality if improperly disposed of. Industrial waste often includes heavy metals, solvents, and chemical byproducts that contribute to environmental contamination and pose threats to human health and ecosystems. Effective management of these toxic components requires specialized treatment and recycling processes to prevent long-term ecological damage.

E-Waste and Industrial Waste Management Strategies

E-waste management emphasizes recycling and safe disposal of hazardous components like lead, mercury, and cadmium found in electronic devices, reducing environmental contamination and health risks. Industrial waste management focuses on waste minimization, treatment technologies such as chemical neutralization and biological processes, and compliance with regulatory standards to mitigate pollution from factories and manufacturing units. Both strategies require integrated approaches involving collection systems, innovative recycling technologies, and stringent enforcement of environmental policies to promote sustainability and resource recovery.

Recycling Challenges: E-Waste vs Industrial Waste

Recycling e-waste presents unique challenges due to the complexity of materials like heavy metals, plastics, and rare earth elements embedded in electronic devices, requiring specialized processes for safe recovery. In contrast, industrial waste often consists of bulk by-products such as chemicals, metals, and slag, which demand large-scale treatment facilities but are more standardized for recycling or disposal. Both streams pose environmental risks, but the hazardous and heterogeneous nature of e-waste complicates recycling infrastructure, regulatory frameworks, and economic viability compared to industrial waste.

Legal Regulations Governing E-Waste and Industrial Waste

Legal regulations governing e-waste and industrial waste differ significantly, with e-waste subject to specialized frameworks such as the Waste Electrical and Electronic Equipment (WEEE) Directive in the EU and the Resource Conservation and Recovery Act (RCRA) in the U.S. Industrial waste regulations often focus on hazardous material handling under laws like the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA). Compliance with these regulations is critical to minimizing toxic environmental impacts and promoting responsible disposal and recycling practices.

Health Risks Associated with E-Waste and Industrial Waste

E-waste contains hazardous materials like lead, mercury, and cadmium, which pose significant health risks including neurological damage and respiratory problems upon improper disposal. Industrial waste often includes toxic chemicals and heavy metals that can contaminate soil and water, leading to chronic diseases such as cancer and organ damage in exposed populations. Both types of waste require stringent management practices to mitigate environmental pollution and protect public health.

Innovations in Reducing E-Waste and Industrial Waste

Innovations in reducing e-waste center on advanced recycling technologies such as robotic dismantling and AI-driven sorting, which enhance material recovery and reduce hazardous landfill disposal. Industrial waste reduction benefits from circular economy models and real-time waste monitoring systems that optimize resource use and minimize emissions. Both sectors are increasingly adopting biodegradable materials and energy-efficient processes to further decrease environmental impact.

Future Trends in Sustainable Waste Management

Future trends in sustainable waste management emphasize the integration of advanced recycling technologies to address the growing volume of e-waste, which contains valuable metals such as gold, silver, and palladium. Industrial waste management is shifting towards circular economy models, prioritizing waste reduction, resource recovery, and energy-efficient processes to minimize environmental impact. Innovations in AI-driven sorting systems and biodegradable materials promise to revolutionize waste processing, enabling more efficient separation and reuse of hazardous and non-hazardous components.

e-waste vs industrial waste Infographic

difterm.com

difterm.com