Lost-wax casting offers exceptional detail and precision, making it ideal for intricate art pet sculptures with fine textures and delicate features. Sand-casting is more cost-effective for larger, simpler shapes but lacks the refined surface quality of lost-wax, often requiring additional finishing work. Artists seeking high fidelity and smooth finishes typically prefer lost-wax, while sand-casting suits robust, less detailed pieces.

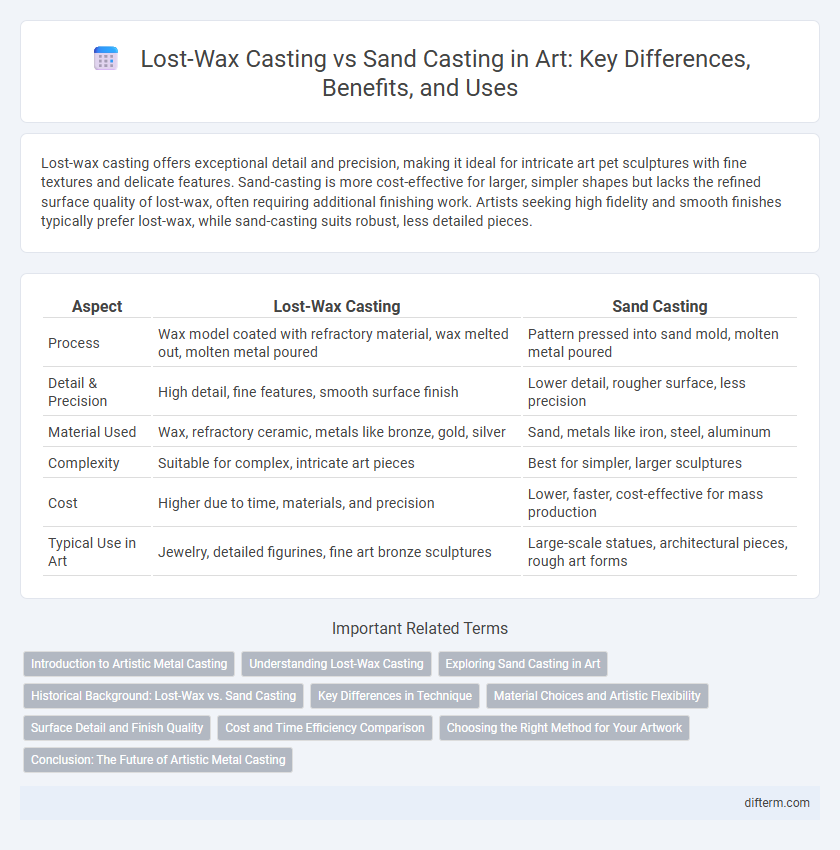

Table of Comparison

| Aspect | Lost-Wax Casting | Sand Casting |

|---|---|---|

| Process | Wax model coated with refractory material, wax melted out, molten metal poured | Pattern pressed into sand mold, molten metal poured |

| Detail & Precision | High detail, fine features, smooth surface finish | Lower detail, rougher surface, less precision |

| Material Used | Wax, refractory ceramic, metals like bronze, gold, silver | Sand, metals like iron, steel, aluminum |

| Complexity | Suitable for complex, intricate art pieces | Best for simpler, larger sculptures |

| Cost | Higher due to time, materials, and precision | Lower, faster, cost-effective for mass production |

| Typical Use in Art | Jewelry, detailed figurines, fine art bronze sculptures | Large-scale statues, architectural pieces, rough art forms |

Introduction to Artistic Metal Casting

Lost-wax casting, a technique dating back thousands of years, involves creating a detailed wax model coated in refractory material to form a mold, then melting away the wax to pour molten metal into intricate designs. Sand-casting uses compacted sand to mold metal, offering flexibility for large-scale or less detailed artistic pieces but with coarser surface textures. Artists select lost-wax casting for precision and fine detail in bronze sculptures, while sand-casting suits bold forms and robust artworks.

Understanding Lost-Wax Casting

Lost-wax casting, a precise and ancient metalworking technique, allows artists to create intricate sculptures by carving a detailed wax model that is encased in refractory material; upon heating, the wax melts away, leaving a mold for molten metal. Unlike sand-casting, which uses a coarser mold and is better suited for larger, less detailed pieces, lost-wax casting excels in producing fine, delicate features and complex shapes with smooth surfaces. This method is favored in art for its ability to capture minute artistic details and produce high-quality bronze statues and jewelry.

Exploring Sand Casting in Art

Sand casting, an ancient technique, allows artists to create intricate metal sculptures by packing sand around a model to form a mold, ideal for large-scale artworks and complex textures. Unlike lost-wax casting, sand casting offers a more cost-effective and faster process, making it suitable for limited editions and experimental designs. This method excels in producing robust, unique metal pieces with surface qualities that enhance the visual depth and tactile experience of contemporary and traditional art forms.

Historical Background: Lost-Wax vs. Sand Casting

Lost-wax casting, also known as cire perdue, traces back over 5,000 years to ancient civilizations such as Mesopotamia and the Indus Valley, renowned for producing intricate bronze sculptures. Sand casting, with origins in ancient China and Egypt, became widespread due to its efficiency in manufacturing larger metal objects using reusable sand molds. Both techniques have distinct historical significance, with lost-wax favored for detailed, artistic pieces and sand casting for mass production in industrial and artistic applications.

Key Differences in Technique

Lost-wax casting involves creating a detailed wax model covered in ceramic material to form a mold, which is then heated to melt away the wax, allowing molten metal to fill the cavity for precise and intricate designs. Sand-casting uses a sand-based mold formed around a pattern, making it suitable for larger and less detailed metal objects with a rougher surface finish. The key difference lies in lost-wax producing finer detail and smoother finishes, whereas sand-casting offers cost-effectiveness and versatility for larger, simpler shapes.

Material Choices and Artistic Flexibility

Lost-wax casting allows for intricate details and complex shapes due to its use of wax models, offering artists greater precision and customization with materials like bronze and silver. Sand-casting tends to be cost-effective for larger, simpler forms but limits fine detail, commonly using metals such as iron and aluminum. The selection between lost-wax and sand-casting directly impacts artistic flexibility, influencing texture, surface quality, and the range of possible material finishes.

Surface Detail and Finish Quality

Lost-wax casting produces superior surface detail and a smoother finish due to its precision mold created from a wax model that captures fine textures. Sand-casting often results in a rougher texture and less refined detail because the sand mold grains can leave irregularities on the surface. Artists favor lost-wax for intricate sculptures where high-quality finish and intricate patterns are essential.

Cost and Time Efficiency Comparison

Lost-wax casting generally incurs higher costs due to the intricate wax model preparation and detailed mold-making process, making it more time-consuming compared to sand-casting. Sand-casting is more cost-effective and faster, utilizing reusable sand molds that simplify production for larger, less detailed metal parts. Artists prioritize lost-wax casting for precision and fine details despite its higher expenses, while sand-casting suits budget-sensitive projects with quicker turnaround requirements.

Choosing the Right Method for Your Artwork

Selecting the appropriate casting method for your artwork depends on factors such as desired detail, size, and material. Lost-wax casting excels in producing intricate, high-fidelity sculptures with smooth surfaces, making it ideal for fine art and complex designs. Sand-casting offers cost-effective and larger-scale options, suitable for robust, coarse-textured pieces where precision is less critical.

Conclusion: The Future of Artistic Metal Casting

Lost-wax casting offers unparalleled precision and detail, making it ideal for intricate artistic metalwork, while sand-casting provides cost-effective versatility for larger sculptures. Advances in 3D printing and hybrid techniques are bridging the gap between these methods, enhancing creativity and efficiency in metal casting. The future of artistic metal casting lies in integrating traditional craftsmanship with innovative technology to push the boundaries of design and expression.

lost-wax vs sand-casting Infographic

difterm.com

difterm.com